Investigate how emissions of PM (particular matter, black carbon, soot, etc) can be further reduced by optimising the aftertreatment system especially the exhaust gas scrubber system but also including EGR and SCR systems, additionally the influence of the fuel was analysed.

Propose robust and practical methods for measuring PM and BC emissions.

The results generated in this project is basically unique, never before in history has a study this big and complicated been performed on the exhaust gas from several large engines with different types of fuel and measured with different kinds of equipment. The results will, as they are published in papers to IMO, have direct influence on future maritime legislation.

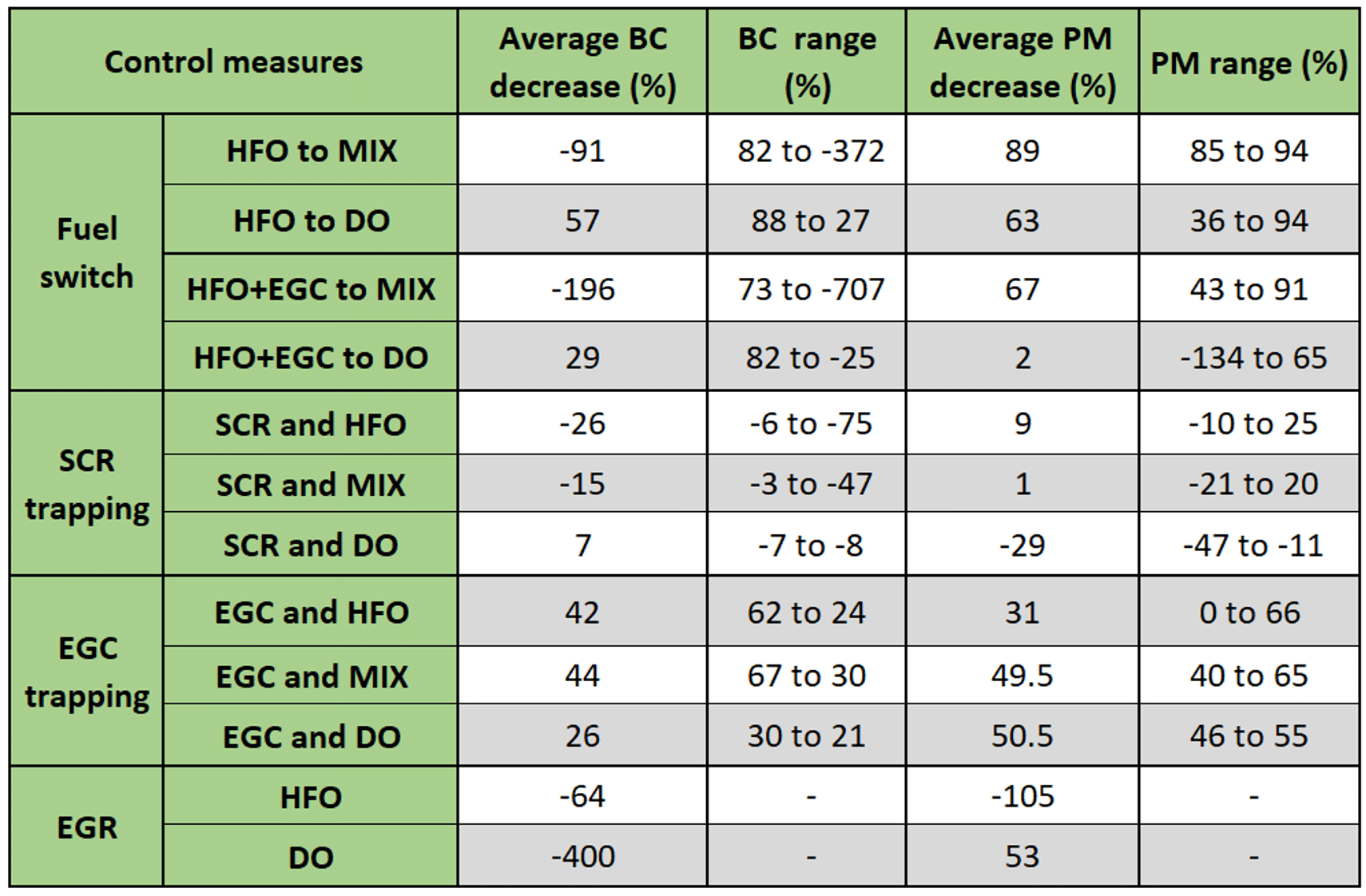

To give a better overview of the results from the project a table have also been inserted as seen in the following: